Our commitment

We have produced pure air equal to

Contaminants eliminated

198'720

2'520 kg

Average air quality in work environments

91

out of 100

* data as at 10 January 2022

![25372-[Convertito].png](https://static.wixstatic.com/media/d022e8_326d200eefad4b0589405d8db743fabc~mv2.png/v1/fill/w_980,h_560,al_c,q_90,usm_0.66_1.00_0.01,enc_avif,quality_auto/d022e8_326d200eefad4b0589405d8db743fabc~mv2.png)

A natural partnership

An ambitious project

Erretre has decided to join the global U-Earth Pure Air Zone project to help clean the air and reduce the toxins we breathe on a daily basis. Gas emissions are increasingly present in our daily lives and Erretre immediately felt the responsibility to respond in person: from constant research to implement the performance of its machines, to the improvement of air quality management with the introduction of innovative solutions, conceived to guarantee higher safety levels and boost quality standards.

Achieving Pure Air Zone certification, which adopts an innovative biotechnology system, is part of a continuous improvement strategy that has always been a key cornerstone of Erretre's vision: to reduce our environmental impact for a more sustainable future.

Measurable benefits and technology

Healthier work environment

Improved safety and work comfort for increased productivity

Boost the growth of Industry 4.0

Sensors and remote control services integrated within Erretre’s technological structure.

Energy saving

A single purification system, reducing air conditioning and relative consumption.

Environmental sustainability

Technology helps reduce air pollution.

![25372-[Convertito].png](https://static.wixstatic.com/media/d022e8_326d200eefad4b0589405d8db743fabc~mv2.png/v1/fill/w_980,h_560,al_c,q_90,usm_0.66_1.00_0.01,enc_avif,quality_auto/d022e8_326d200eefad4b0589405d8db743fabc~mv2.png)

Erretre obtains Pure Air Zone certification for a healthier environment

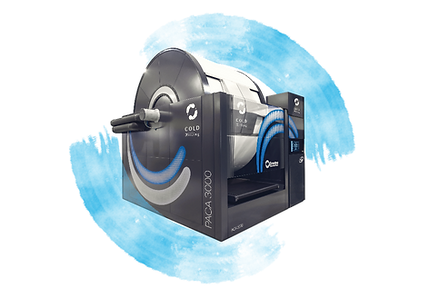

Thanks to the U-Earth purification devices, Erretre will help reduce air pollution by eliminating up to 7 kg of contaminants every day, the depolluting power of a forest of 552 oak trees.

These products reduce air pollution by attracting pollutants using a molecular electric charge and destroying them using biotechnological additives.

Attention to the environment and a cutting-edge approach has always been distinguishing elements of Erretre.

Air purification technology at the service of people

# 1 CAPTURE

Electric molecular attraction.

A unique biophysical principle is capable of attracting all particles that would never respond to gravity and ventilation: down to the smallest and most harmful sizes and types, including gases, mold spores, superfine particles, VOCs and pathogens between which SARS-CoV-2.

Three orders of magnitude better than the others.

# 2 DESTROYS

Naturally digested compounds.

H2S + O2

Now that all the contaminants have been attracted into the air purifiers, here is the efficiency of natural bio-oxidation in digesting the compounds into water + carbon dioxide (a very small amount from cellular respiration) and an elemental base if present.

=

H2O + CO2 + S

H2S management example.

# 3 MONITOR

IoT data in real time.

With U-earth it is possible to monitor the cycle of the air purification system making sure that the performances are always at their maximum capacity.

Air quality specialists can remotely follow the real-time air quality situation in the treated plant and report on system performance.

U-monitor pictures.

# 4 TRACK

Track your performance.

U-earth's mission is to generate a global impact. To do this they created the Pure Air Zone certification, currently used by the best brands in the world. Each certified Pure Air Zone becomes part of the Pure Air Zone Dashboard, where the quantities of contaminants destroyed each day by each of them are calculated.

Erretre is proud to be part of this commendable project.

Pure Air Zone dashboard.

Source: https://it.u-earth.eu/technology

A pioneering vision targeting the integration of new technologies is critical to improving the lives of the people we work with.

U-Mask integration within the workplace

Together with the U-Earth project, Erretre decided to adopt the use of its facilities of the U-Mask, the world's first biotech mask. These masks are a new cutting-edge product that exploits the power of biotechnology. U-Mask not only blocks air contaminants on the face of the mask, but it destroys them inside.

Erretre constantly develops and applies technologies aimed at increasing safety and technological innovation. The introduction of the U-Mask is just the latest step taken to improve the work environment and contribute to protecting the safety of the people that work there.

Layers and structure of U-Mask.

Erretre's green soul

Erretre has always designed and produced its high-tech machinery with a view to sustainability, reducing waste and optimising consumption.

ECOTAN

56 g

Dusts in the air *

420 g

Previous models

* On average during a work shift

of filtered air per day

43,200 M

3

Energy saving

Energy-saving has always been a key cornerstone in every Erretre project: from the careful choice of materials to the reduction of waste.

But the true green heart of the Erretre machines is the exceptional level of technology. Their functions are constantly adjusted to meet actual needs, hence optimising consumption.

A tangible commitment to reducing pollution.

Discover other products